The printing press is a useful tool, it holds the mesh screen firmly between prints. Printing companies may use glittery inks, puff inks, or texturized inks to give their silk screen production a unique look. For fine screen printing, there are specialized inks that create excellent effects on the final product. The pigments or the inks used for silkscreening play an important role as there are so many options to choose from. Ink is poured onto the mesh and pressed down on the item being printed. The thickness, texture, and thread count of the mesh screen determine the quality of the final print. But nowadays, there are many options commonly crafted from polyester fabric. Originally the mesh screens were made from silk thread, hence the name. The transplant film is placed on the mesh screen to imprint the stencil.

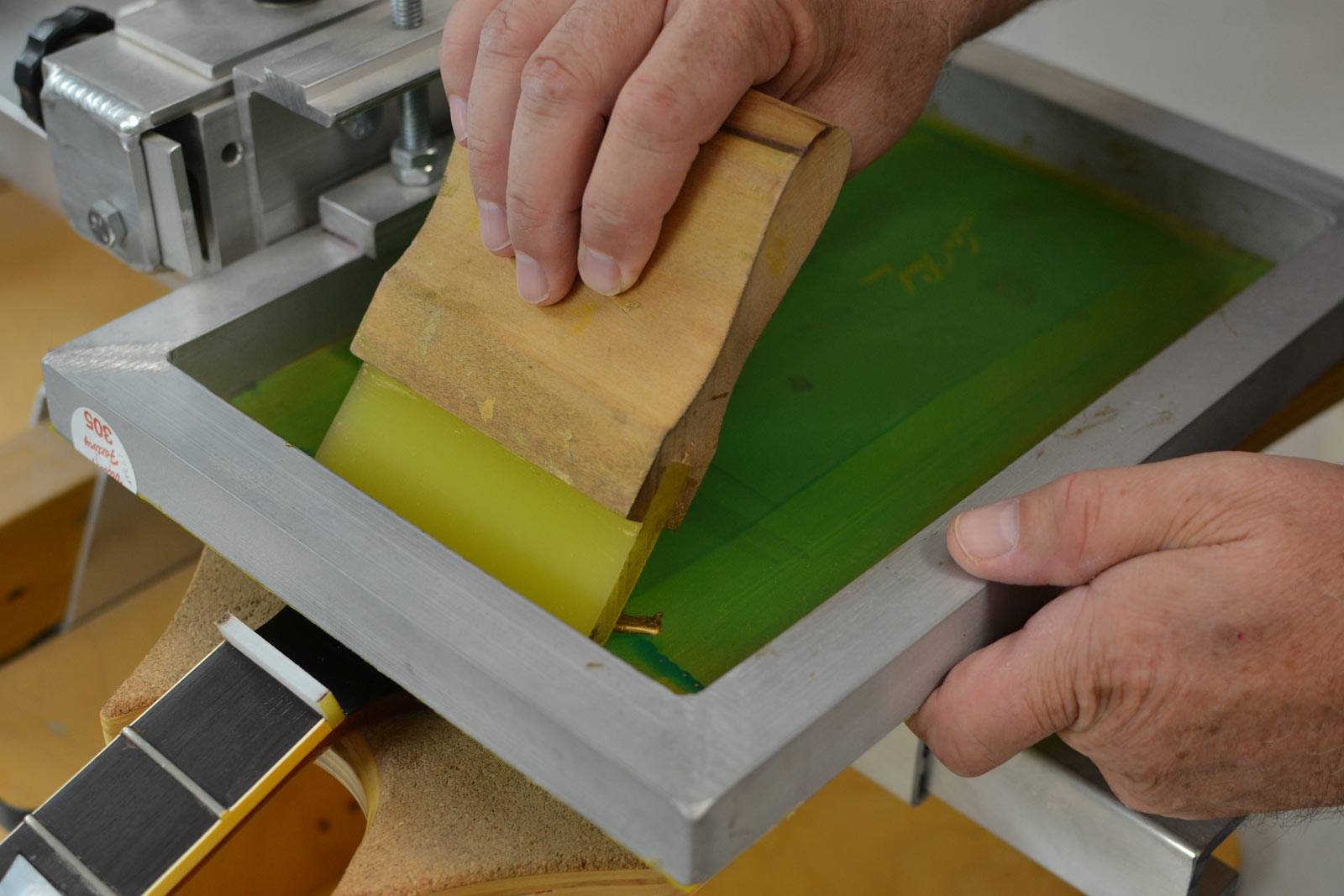

The most important material in silkscreen printing is a mesh screen. For each color, different acetate films are used and they are later on used for creating stencils. The required design is taken out onto a transparent film called acetate film. The first thing that you need in custom silk screen printing is a printer that can be used to create designs on the stencils. Here is a list of all the materials used in silk screen printing: The mesh screen is washed off with special chemicals before the next use.įor complete silk screen production, there are several different tools ad materials needed. The final product is washed and checked for residue before sending out into the market. Step 7: After transferring the ink onto the item, it is completely dried up using a dryer. For printing multiple items, a new item is placed underneath the screen and the process is repeated. When the ink is pushed from the screen, it creates the imprints of the design onto the fabric. A squeegee is then used to press the ink from the screen onto the item. Step 6: The screen is lowered to come in contact with the fabric and ink is poured on the screen. The fabric or the paper which is to be printed is placed on a printing board, below the screen. For multicolor printing, an automatic printing press works best as it can apply individual color coats quickly. In the modern process, there are many different types of printing presses used, some are automatic, some manual. Step 5: The mesh screen with the design is set up on the printing press with screws. The screen is completely dried after the wash-up and the stencil is prepared to be used. That creates a perfect imprint of the required design on the mesh screen which is later used for silk printing. Any area of the emulsion that was not hardened by the light is washed away. Step 4: After a certain time, the portions on the screen not covered by the design turn hard. If the design has different colors, a separate mesh screen is used for each color ink. Step 3: The acetate sheet with the design is placed on the mesh screen and both are exposed to a bright light, which makes the emulsion hard. The suitable mesh screen is then covered with a layer of light-sensitive emulsion. Step 2: Next, the mesh screen is chosen, according to the difficulty of the design and the type of fabric or other material used for printing. The design or pattern selected is then printed onto a transparent acetate film by the printer. Step 1: The first thing needed in the silk screen process is an original image from where the printer copies the design.

The silk screen process can be explained in detail using the following steps: Different materials used for making stencils include vinyl, polish and light-sensitive emulsions. The silk screen process can be distinguished by the way stencils are created for prints. Silk screen printing may use just one or multiple colors of ink for printing.įor multicolored prints, a separate stencil is used for each ink in an individual layer. Silk screen printing is most commonly used for fabrics, canvases, and posters but with special inks, it has been used for printing all sorts of things like wood, glass, and ceramic, etc.

The shirt you are wearing or the mug you drink your coffee in might have a print created by this method. Silk screen printing is a famous technique, used in almost all industries today. Seicos, which means silk, and graphos, meaning writing. It is often known by the name Serigraph, which is a blend of two Greek words. Silkscreen printing, also called screen printing is an ancient method of using ink through a stenciled mesh to create printed designs. The Complete Guide On Silk Screen Printing

0 kommentar(er)

0 kommentar(er)